Company / Startups

Company / Startups

Every startup needs to manage their costs effectively if they’re going to survive. That means working with a small team and only spending money on things that are absolutely necessary. Unfortunately, there are a lot of costs that you simply can’t avoid and manufacturing costs are a big one. Most startups are likely to outsource their manufacturing to a third party because they don’t have the capital to set up their own manufacturing operation. In most cases, that’s a sensible option, however, there are some downsides.

You don’t have as much control over the process and the quality of the product might not meet your standards. You may also run into issues if your product is particularly complex and manufacturing companies struggle to get it right. If you’re selling products at a high price point and your focus is on quality, it may be best to set up your own manufacturing operation. Once you’ve covered the cost of setting it all up, you will save money on your manufacturing so it’s a good idea if you can afford it. That said, you still need to make sure that you’re not overspending on manufacturing, otherwise, it will eat into your profit margins and you will struggle with cash flow problems. If you’re thinking about setting up your own manufacturing for your startup, these are some of the best ways to keep the costs down.

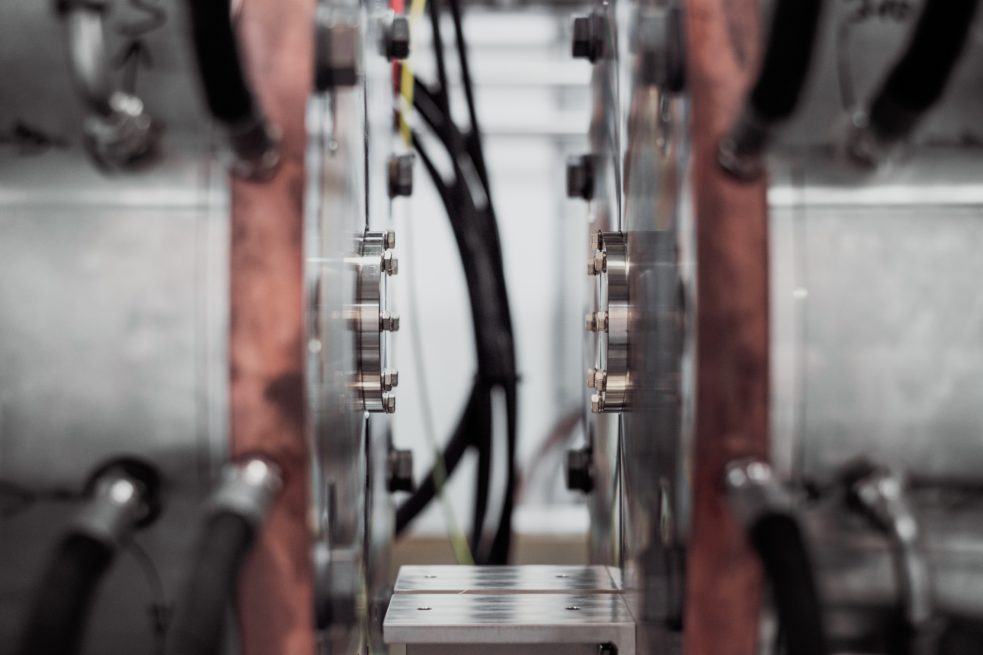

Buy Second Hand Machinery

Buying all of the machinery is the biggest cost that you’ll have to bear and if you buy everything brand new, the costs will quickly spiral out of control. Manufacturing equipment is so expensive but you can save yourself quite a bit of money if you buy second hand instead. You won’t have all of the same features that you find on brand new machinery but the basic functions will be the same. You can still manufacture good quality products with second hand machinery and it will save you a lot of money. However, you do need to strike a balance because newer equipment is usually more efficient and has better safety features so you don’t want to buy things that are 20 years old. But if you get something that is 5 to 10 years old, it won’t be that much different to a brand new machine but it’ll be a lot cheaper.

Preventative Maintenance

Maintenance is another big cost that you’ll have to bear and it’s more of a problem if you’re using older machines that are more likely to break down. Breakdowns are expensive because you not only have to pay for repairs but you also have to bear the costs associated with a stop in production for a while. If you have serious repairs to do and your manufacturing operation is shut down for a day or two, you’ll be very behind and it might even mean having to let customers down and deliver products late.

The easiest way to save money on maintenance and avoid any shutdowns is to do preventative maintenance. If you clean your machines properly and check them regularly for any small issues, you can deal with them outside of production hours so they don’t affect your output and they don’t develop into more serious problems. You should also implement condition monitoring services to help maximise machine efficiency by identifying any problems early on. When a machine is in bad condition and parts need replacing soon, you’ll be identified right away so you can fix problems before they happen. If you don’t carry out preventative maintenance and you just wait until something breaks before you fix it, you’ll waste a lot of money and your output will drop drastically.

Price Products Accurately

Pricing is another thing that causes people big problems with their manufacturing when they’re first starting out. Obviously, you want to be competitive on price and if you’re a startup, you need to work hard to find new customers. That means a lot of startups make the mistake of pricing their products very low to draw people in. Offering a low price is fine as long as you can actually afford to manufacture and sell your products at that price but a lot of startups find themselves in a position where they can’t. The manufacturing costs end up being a lot higher than they thought and they realize that they’re not making much profit at all on their products.

If you’re in this situation, you have 2 options; you could find ways to manufacture the product for less money, but that usually means a reduction in quality. Alternatively, you’ll have to increase the prices to something more realistic. When you’re trying to price products, you should use analytics from the pricing page on your website to gauge your customer’s spending habits. If people are willing to pay a bit more for a better quality product, you can afford to up your prices. If they aren’t, you need to look at ways to manufacture the product for less money while still maintaining quality and that usually means spending a lot more on your manufacturing equipment.

If you’re realistic about price initially, you shouldn’t have this problem but if you come in with a low price and then suddenly increase it, customers are far less inclined to pay the higher price. That means you’ll have no choice but to invest a lot of money in better manufacturing equipment.

Negotiate Material Costs

This is a simple thing that a lot of new startups don’t do, and it wastes a lot of money. When you’re sourcing the raw materials to manufacture your products, you always need to negotiate on price. A vendor isn’t going to offer you their lowest price right away so don’t accept the deal immediately. Shop around a bit and compare prices, then you can go back to a vendor and tell them that you can get a better deal elsewhere and see if the can match it. Often, they will agree to match it and if you go back and forth between vendors a few times, you can knock the price down quite a bit.

There are a lot of benefits to setting up your own manufacturing operation and you can save yourself money in the long term, but it’s vital that you keep costs down to start with, otherwise, you’ll run into some serious cash flow problems.